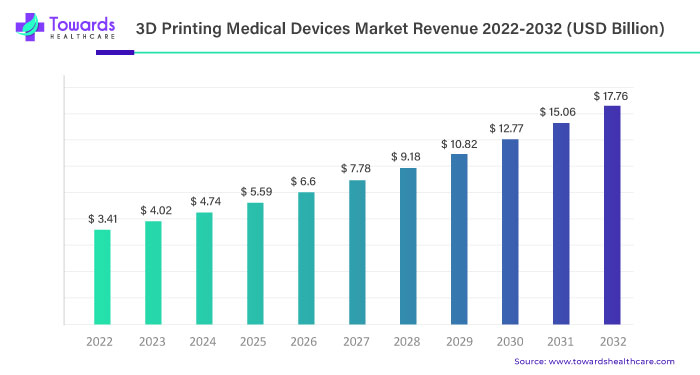

The 3D printed medical devices market for these cutting-edge products is poised for exceptional growth, projected to surge from USD 3.41 billion in 2022 to an estimated USD 17.76 billion by 2032, boasting a compelling 17.94% compound annual growth rate (CAGR) during the period from 2023 to 2032. This extraordinary expansion is fueled by an escalating demand for tailor-made 3D printed solutions, redefining the way healthcare operates.In the ever-evolving landscape of healthcare, 3D printed medical devices market are spearheading a transformative wave.

Customization Driving Growth: A 3D Printed Medical Devices Market

Perspective

Customization and Personalization in 3D Printed Medical Solutions are Causing Massive Growth in the Medch Field.

The solutions provided by the 3D printing medical devices industry cover a wide range of revolutionary medical and industrial applications. 3D printing has progressed from its beginnings as a prototyping technology to a feasible choice for end-use regions and larger-scale manufacturing applications. 3D printing has expanded beyond consumer markets in the past few years, developing itself as a commonly utilized commercial method of production. In the past two years industry developments have positioned the technology to move beyond its applications in effective prototyping and become an appropriate approach for end-use regions and serial manufacturing.

The COVID-19 pandemic emphasized 3D printing’s distinctive capacity to rapidly respond to production as well as supply chain requirements. Because parts and products can be manufactured locally and on-demand, 3D printing has emerged as an appealing option to new and constant challenges.

During the COVID-19 pandemic manufacturers used 3D printing to manufacture medical devices and protective equipment (PPE) such as ventilator valve replacement parts, face shields, and others at a rapid pace. The use of 3D printing in medical device manufacturing could help manufacturers overcome supply chain issues and shortages that occurred due to the pandemic. Additionally, manufacturers started 3D printing nasal swabs for COVID-19 detection, which illustrated the viability of mass production. Due to this 3D printed medical devices market experienced a boom during the COVID-19 pandemic.

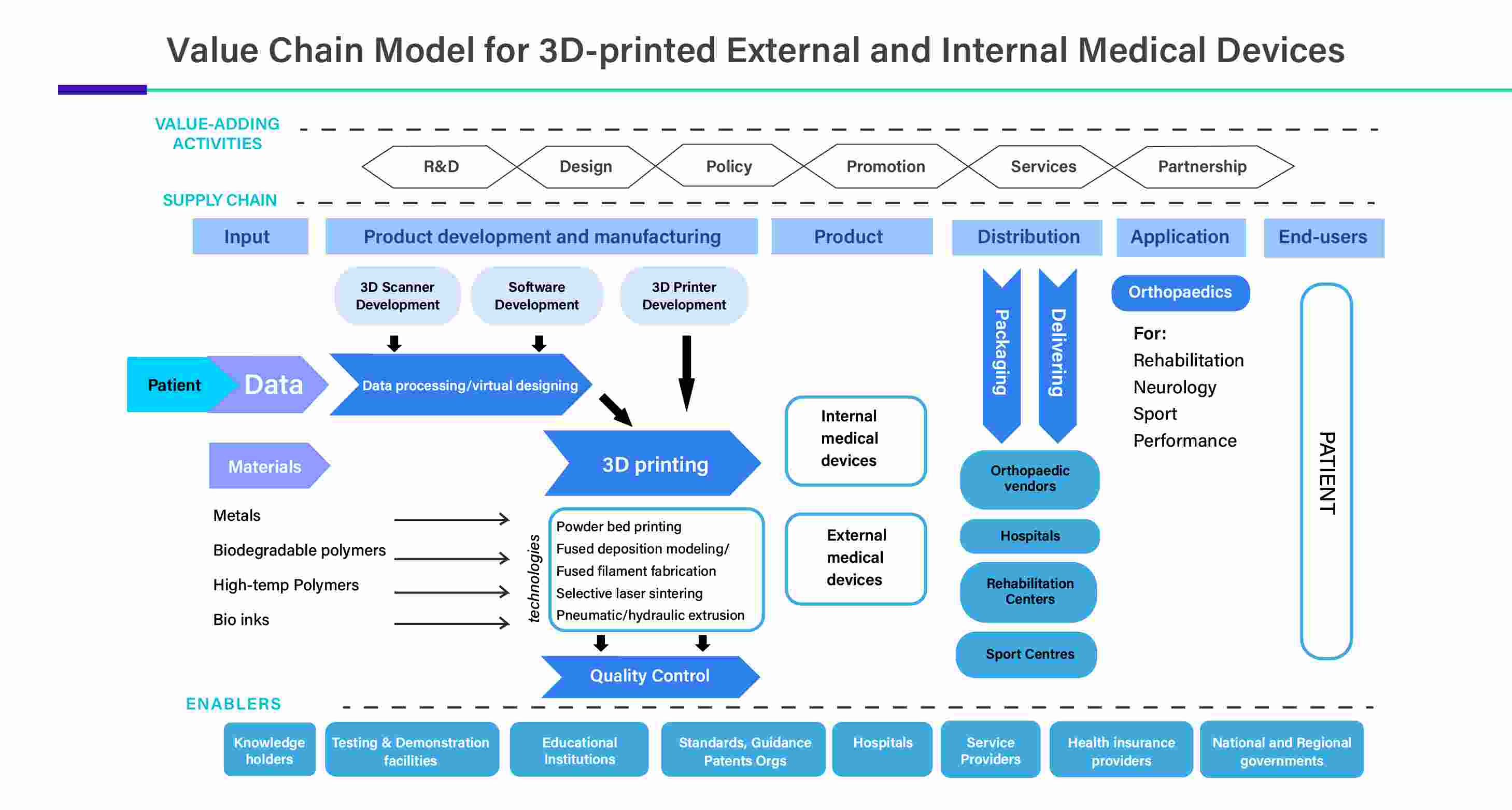

Connection Among Players in the Value Chain is Necessary

Since patient care is at stake, many crucial considerations exist in 3D-printed medical device manufacturing. Because of this, the value chain for 3D-printed medical devices is particularly complicated and calls for the participation of actors with varied backgrounds. Developing the value chain for 3D-printed medical devices requires close coordination between all the important players. The various actors in the value chain lack coordination and cooperation. As a result, collaboration is also hampered by the use of various 3D printing processes and interfaces.

Additionally, manufacturers of medical devices ought to be more aware of the effects that the upstream and downstream processes have on the finished product. In its new complete guidance for medical device manufacturers, the US Food and Drug Administration (FDA) adamantly emphasizes this significance. Currently, instead of operating in cooperation, activities frequently run in competition.

The Costs of Medical Devices are Tackled with 3D Printing

The Costs of Medical Devices are Tackled with 3D Printing

The healthcare industry has experienced a revolutionary transformation with the advent of 3D printing medical devices technology. The healthcare industry has been ultimately impacted by the high cost of medical devices over the years, as traditional medical device manufacturing follows expensive and lengthy processes which accelerates the overall cost of production. On the other hand, 3D printing provides an efficient and cost-effective alternative in which medical devices are directly manufactured with the help of digital designs. This eliminates a number of labor-generated steps and complex processes involved in traditional manufacturing.

In order to create precise prototypes of medical devices as well as equipment and tools to streamline testing, more than 90% of the biggest medical device manufacturers use 3D printing. Cost savings of up to 70% were reported by one medical device manufacturer. In addition, according to a different medical research organization, using 3D-printed models in 10-15% of cases could result in annual savings of up to $1,750,000.

Custom-fit prosthetics are frequently expensive and only available to patients in developed nations who have insurance. To overcome these financial obstacles, prosthetics are increasingly utilizing the adaptable design of 3D printing. Making surgical instruments with 3D printing medical devices is an efficient and affordable way to manufacture in-demand medical supplies. Even for complicated instruments, it is effortless to alter designs for surgical requirements.

Furthermore, 3D printing offers customization and personalization which involves the creation of patient-specific medical devices. This reduces the need for costly replacements and improves patient outcomes. Surgery guides and implants that precisely fit a patient’s anatomy are made using 3D printing. This lessens the possibility of issues, expensive modifications, and protracted hospital stays. By enabling on-demand and localized production, 3D printing eliminates the need for vast shipping and warehousing networks, which can be expensive.

Customization and Personalization are Expanding the Market Growth

3D Printed medical devices are usually produced in limited quantities, and patterns can be modified continually to reduce costs, weight, and component counts to produce small, lightweight medical devices with internal performance. Medical devices that are specifically designed for a patient enhance comfort, fit, and outcomes while lowering the risk of complications. With numerous applications in interbody, dental, surgical, orthopedic, and personalized devices, 3D printing earnings in the medical devices sector have been increasing continuously since 2018.

Custom implants and prosthetics can be made using 3D printing to better fit a patient’s needs and increase comfort and functionality. Using surgical guides that were 3D printed, surgeons can perform complex procedures like spinal replacements and joint replacements with greater precision and accuracy, increasing their chances of success and speeding up their recovery. This leads to devices that are better matched to the patient and their particular anatomy.

Unveiling the Market Dynamics

The exponential growth anticipated in the 3D printed medical devices market is intricately linked to the increasing need for personalized healthcare solutions. Traditional manufacturing methods often fall short in providing the level of customization required to meet individual patient needs. 3D printing emerges as the solution, offering a versatile and efficient approach to crafting medical devices tailored to specific anatomical structures and patient requirements.

Meeting Demand through Technological Advancements

Advancements in 3D printing technology play a pivotal role in expanding the market’s horizons. With continuous innovations, the industry is witnessing the development of more sophisticated and precise 3D printing techniques. This evolution ensures not only enhanced customization but also elevates the overall quality and functionality of medical devices, propelling the market towards unprecedented growth.

Unveiling the Growth Trajectory: A Comprehensive Outlook

Forecasting the Market Expansion

The projected CAGR of 17.94% from 2023 to 2032 signals a robust and consistent upward trajectory for the 3D printed medical devices market. As healthcare providers increasingly recognize the benefits of customized solutions, the demand for 3D printed devices is expected to soar, creating ample opportunities for market players and stakeholders.

Key Factors Fueling Market Growth

- Rising Patient-Centric Approach: The shift towards patient-centric healthcare propels the demand for personalized medical devices, driving the market’s expansion.

- Economic Viability of 3D Printing: The cost-effectiveness of 3D printing, coupled with its ability to reduce material wastage, contributes significantly to market growth.

- Streamlined Prototyping Processes: 3D printing facilitates rapid prototyping, allowing for quicker iterations and innovation in medical device design.

- Collaborations and Partnerships: Increasing collaborations between healthcare providers and 3D printing companies foster innovation and drive market growth.

Beyond Numbers: The Implications for Healthcare

Enhancing Patient Outcomes

The surge in 3D printed medical devices isn’t just about numbers; it signifies a paradigm shift in patient care. Customized implants, prosthetics, and surgical tools empower healthcare professionals to deliver more precise and effective treatments, ultimately improving patient outcomes.

Redefining Medical Possibilities

As 3D printing continues to advance, the scope of possibilities within the medical field expands. From intricate organ models for pre-surgical planning to on-demand production of specialized implants, the technology reshapes the landscape of medical possibilities, setting the stage for a new era in healthcare.

High Growth Opportunities in Radiation Oncology

3D printing provides customizable and affordable solutions for the making of anthropomorphic radiotherapy phantoms through in vitro methods. Such phantoms are significantly used for the treatment planning of cancer patients and make sure that innovative radiation procedures are subject to quality assurance (QA). These phantoms make use of 3D printing technology to allow preliminary confirmation of customized radiation doses and to lessen the adverse effects of ionizing radiation on nearby healthy tissues.

In addition, the increasing rate of commercial accessibility and availability especially in case of medical technology with the intervention of 3D printing, ave created extensive growth opportunities in the medical technology sector. 3D printing also provide opportunities for inexpensive producers of personalized medical devices for radiotherapy phantoms as well as radiotherapy devices consisting of bolus & compensators to attain customized dose distribution intended for electron beam shielding devices, irregular surfaces, brac, brachytherapy and several others. This further bolsters the extent of growth opportunities in the 3D-printed medical devices market. Furthermore, market players can further expand their capacities and avail themselves of more profits in the field by establishing collaborations with other healthcare and technology market players.

In June 2022, Adaptive Medical Technologies, Canada based firm in software and medical device development, collaborated with Varian (Siemens Healthineers Company) and HP Inc. to use 3D-printed medical devices to improve the standard of and patient access to personalized cancer care in the United States. Adaptive Medical Technologies have developed software that aligns with 3D printing technology to make medical devices that can be effectively used in radiation oncology.

Major Market Players

- 3T RPD Ltd.

- Renishaw plc.

- Concept Laser GmbH

- GENERAL ELECTRIC

- Arcam AB

- EOS GmbH Electro Optical Systems

- Materialise

- ENVISIONTEC, INC.

- 3D Systems, Inc.

- Stratasys Ltd.

- Cyfuse Biomedical K.K.

- ORGANOVO HOLDINGS, INC.

Market Segments:

By Products

- Dental Products

- Cardiovascular Products

- Neurological Products

- Orthopedic Products

- Cranio-maxillofacial Products

- Others

By Technology

- Fused Deposition Modelling (FDM)

- Bioprinting

- Selective Laser Sintering (SLS)

- Electron Beam Manufacturing (EBM)

- Stereo-lithography

- Binder Jetting

- Others

By Application

- Medical

- Pharmaceutical

- Others

By End User

- Hospitals

- Research Centers

- Pharmaceutical & Biotechnology Companies

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Conclusion: A Future Envisioned

In conclusion, the 3D printed medical devices market’s remarkable growth trajectory reflects a future where healthcare is increasingly personalized, precise, and efficient. As technological advancements and demand harmonize, the synergy propels this revolutionary industry towards a future where customized healthcare solutions are not just a possibility but a standard practice. Embracing the potential of 3D printing in the medical realm is not merely an evolution; it’s a revolution with far-reaching implications for the well-being of individuals worldwide.