3D-Printed Medical Devices Market Analysis and Company Insights (2023 – 2032)

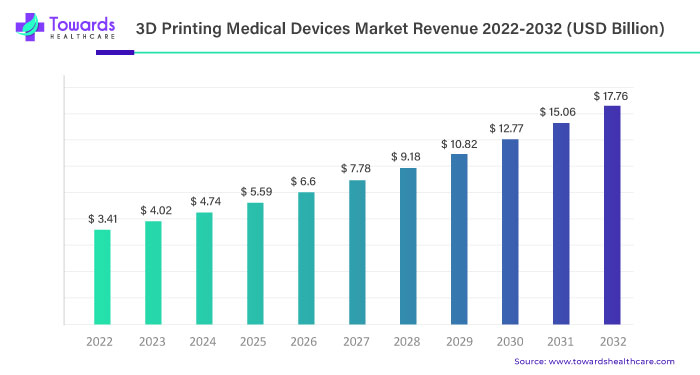

The 3D-printed medical devices market is expected to grow significantly, from USD 3.41 billion in 2022 to an estimated USD 17.76 billion by 2032, reflecting a compound annual growth rate (CAGR) of 17.94% from 2023 to 2032. This growth is driven by increasing demand for customized 3D-printed medical solutions.

Download statistics of this report @ https://www.towardshealthcare.com/download-statistics/5072

The Surge of Customization and Personalization in 3D-Printed Medical Devices

The 3D printing industry has revolutionized medical and industrial applications, moving beyond its origins in prototyping to become a viable choice for end-use products and large-scale manufacturing. Over the past few years, the technology has expanded beyond consumer markets and is now widely adopted in commercial production. Significant industry advancements have allowed 3D printing to evolve from a prototyping tool to a key player in manufacturing and end-use applications.

The COVID-19 pandemic highlighted the unique advantages of 3D printing in addressing production and supply chain challenges. With the ability to manufacture parts locally and on demand, 3D printing proved to be a valuable solution during times of crisis. During the pandemic, manufacturers used 3D printing to quickly produce critical medical devices and protective equipment (PPE), such as ventilator valve parts, face shields, and even nasal swabs for COVID-19 testing. This showcased the potential for mass production and helped the 3D-printed medical devices market boom.

Key Trends in the 3D-Printed Medical Devices Market

- Patient-Specific Solutions: The market is increasingly focused on creating personalized medical devices tailored to individual patients, improving treatment outcomes.

- Healthcare Expertise: The healthcare sector is leading the charge, with a strong understanding of regulatory requirements and technological applications.

- Long-Term Growth: A strong pipeline of innovations supports continued growth in the market.

- Market Expansion: There is growing interest in entering new markets and increasing the adoption of 3D printing in existing ones.

- Automation: The use of automation is on the rise in the 3D printing process, including the integration of collaborative robots (cobots) and post-processing techniques.

Collaboration Across the Value Chain

Given the critical nature of patient care, the 3D-printed medical device industry requires careful coordination among various players. The value chain for these devices is complex, with multiple stakeholders—each with distinct expertise—needing to work together. However, there is a lack of cooperation due to different 3D printing processes and systems, which complicates collaboration. Manufacturers must also pay closer attention to how upstream and downstream processes impact the final product, as emphasized in recent guidelines from the US FDA.

Lowering the Costs of Medical Devices

3D printing is helping reduce the high costs associated with medical device manufacturing, which often involves expensive and time-consuming traditional processes. By using digital designs to directly manufacture devices, 3D printing eliminates many labor-intensive steps and complex procedures that traditionally drive up production costs.

Over 90% of the largest medical device manufacturers now use 3D printing for prototyping and creating equipment and tools for testing. This has led to significant cost savings—one manufacturer reported saving up to 70% on production costs. Additionally, using 3D-printed models in 10-15% of cases could save up to $1.75 million annually.

3D printing is also making custom-fit prosthetics more affordable and accessible. Traditionally expensive, these prosthetics are now being designed using 3D printing to reduce costs and offer personalized solutions to patients, even in developing countries. Surgical instruments are also being manufactured more efficiently through 3D printing, with designs easily adapted for specific needs.

By enabling on-demand and localized production, 3D printing eliminates the need for extensive shipping and warehousing, further reducing costs. Custom medical devices, such as implants and surgical guides tailored to a patient’s unique anatomy, are improving outcomes and reducing the need for costly replacements, lengthy hospital stays, and complicated modifications.

Our Table of Content (TOC) covers key healthcare market segments, materials, technologies and trends—helping you navigate market shifts and make informed decisions: https://www.towardshealthcare.com/table-of-content/3d-printed-medical-devices-market

Access exclusive insight now @ https://www.towardshealthcare.com/price/5072

We’ve prepared a service to support you. Please feel free to contact us at sales@towardshealthcare.com

Web: https://www.towardshealthcare.com

Visit Dental Specifics: https://www.towardsdental.com

Get the latest insights on industry segmentation with our Annual Membership: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-healthcare