3D Printed Medical Devices Market Trends

The 3D-printed medical devices market is witnessing significant trends that are reshaping the landscape of healthcare delivery. Here are the key trends driving innovation and growth in this dynamic industry:

1. Patient-Specific Solutions and Innovative Delivery Strategies Market trends emphasize a shift towards patient-centric solutions and novel delivery approaches, leveraging the customization capabilities of 3D printing technology.

2. Healthcare Competency and Technological Advancements Healthcare stakeholders are leading the charge in competency, demonstrating expertise in applications, regulatory compliance, and technological advancements, driving the adoption of 3D-printed medical devices.

3. Long-Term Growth and Opportunities The market benefits from a robust pipeline of opportunities, supporting sustained long-term growth and expansion into new markets, alongside the widespread adoption of 3D printing in existing markets.

Download a sample of this report @ https://www.towardshealthcare.com/personalized-scope/5072

4. Automation and Collaboration Automation is becoming integral throughout the 3D printing process, particularly with the incorporation of collaborative robots (cobots) and enhanced post-processing techniques. However, effective collaboration among stakeholders in the value chain remains essential for success.

5. Value Chain Complexity and Coordination The value chain for 3D-printed medical devices is intricate, requiring coordination among diverse stakeholders. Close collaboration is hindered by the use of various printing processes and interfaces, highlighting the need for streamlined workflows and cooperation.

6. FDA Guidance and Regulatory Compliance Recent FDA guidance underscores the importance of considering upstream and downstream processes in medical device manufacturing, urging manufacturers to prioritize cooperation over competition to ensure product quality and patient safety.

7. Cost Reduction and Efficiency 3D printing technology addresses the high costs associated with traditional manufacturing processes, offering an efficient and cost-effective alternative. Significant cost savings, up to 70% in some cases, have been reported by medical device manufacturers through the adoption of 3D printing.

8. Customization and Personalization The ability to create patient-specific medical devices through 3D printing reduces the need for costly replacements and enhances patient outcomes. Custom-fit prosthetics and surgical instruments are becoming more accessible and affordable, driving improved healthcare delivery.

9. Supply Chain Optimization On-demand and localized production facilitated by 3D printing minimizes the reliance on vast shipping and warehousing networks, leading to cost reductions and operational efficiencies across the supply chain.

Expanding Market Growth in 3D Printed Medical Devices: Customization and Personalization Driving Innovation

The landscape of medical device manufacturing is undergoing a profound transformation with the advent of 3D printing technology. Customization and personalization have emerged as key drivers of market growth, revolutionizing the production of small, lightweight medical devices with enhanced performance and tailored to individual patient needs.

Traditionally, medical devices were mass-produced, often leading to suboptimal fit and outcomes for patients. However, with 3D printing, manufacturers can create bespoke implants and prosthetics that perfectly match the patient’s anatomy, significantly improving comfort and functionality. Surgical guides produced through 3D printing enable surgeons to perform complex procedures with unprecedented precision, reducing the risk of complications and expediting recovery.

Examples of personalized medical devices include orthopedic implants custom-designed to fit the shape of bones and adaptable prosthetic leg sockets tailored to the patient’s body mass index and lifestyle. The marginal cost of customization in 3D printing is minimal, as the technology allows for automated workflows from design to production, resulting in cost-effective and scalable solutions.

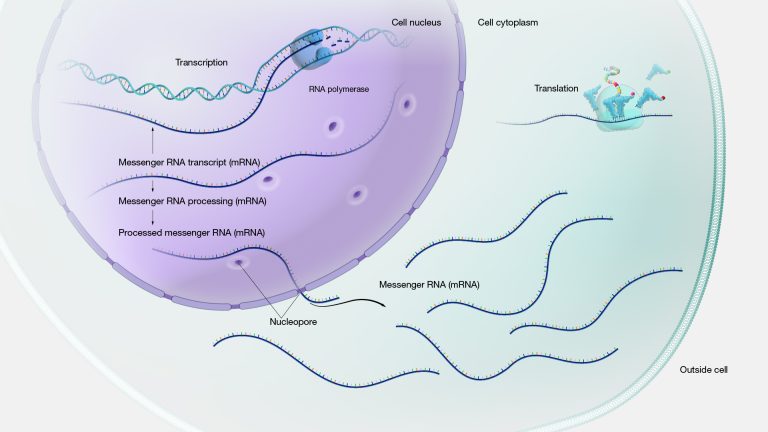

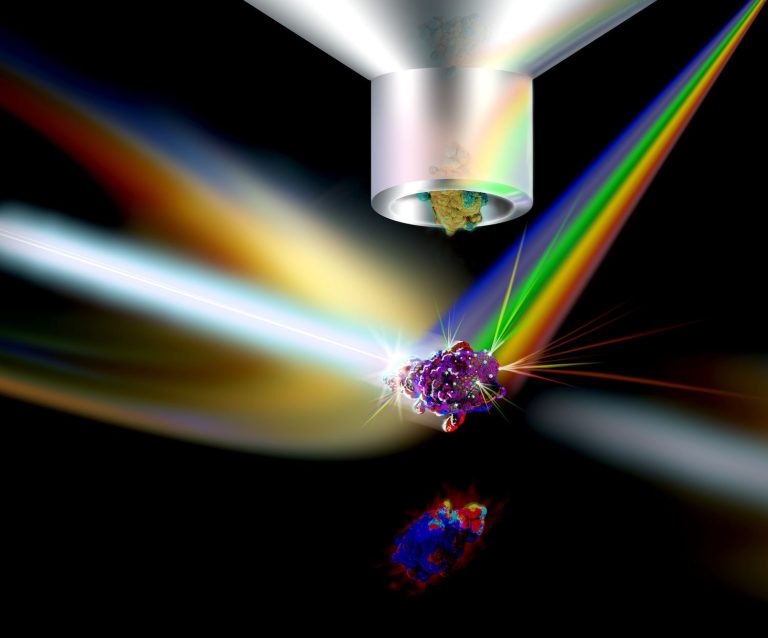

Furthermore, 3D printing enables the fabrication of biologically relevant structures that are impossible to manufacture using traditional methods. Medical professionals can leverage medical imaging data to create patient-specific implants using advanced additive manufacturing techniques, such as selective laser melting (SLM), with biocompatible materials like titanium alloys.

Investments in 3D printing for medical applications are on the rise, driving the development of innovative solutions. Initiatives such as the NSF’s LEAP-HI program support research and development in 3D-printed smart devices, including pediatric ventilation masks, fostering collaboration between academia and industry to address healthcare challenges.

However, stringent regulatory requirements, particularly by agencies like the FDA, present challenges to market growth. Compliance with regulatory standards is essential for ensuring the safety and efficacy of 3D-printed medical devices, requiring manufacturers to navigate complex approval processes.

Despite regulatory hurdles, high-growth opportunities abound in areas like radiation oncology, where 3D printing offers customizable and cost-effective solutions for treatment planning and quality assurance. Collaborations between industry players, such as Adaptive Medical Technologies, Varian, and HP Inc., are driving innovation in personalized cancer care through the development of 3D-printed medical devices tailored to specific patient needs.

To own our research study instantly, Click here @ https://www.towardshealthcare.com/price/5072

Read More about 3D Printed Medical Devices Market:

You can place an order or ask any questions, please feel free to contact us at sales@towardshealthcare.com

About Us

Healthcare Web Wire is a premier subsidiary of Towards Healthcare, dedicated to providing comprehensive insights and information related to the healthcare industry. With a commitment to delivering accurate and timely updates, Healthcare Web Wire serves as a vital resource for professionals, enthusiasts, and stakeholders within the healthcare sector. Our platform serves as a central hub for the latest news, trends and developments shaping the healthcare landscape. Join us on Healthcare Web Wire and become part of a vibrant community dedicated to advancing healthcare knowledge and shaping the future of healthcare worldwide.

Explore the comprehensive statistics and insights on healthcare industry data and its associated segmentation: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-healthcare