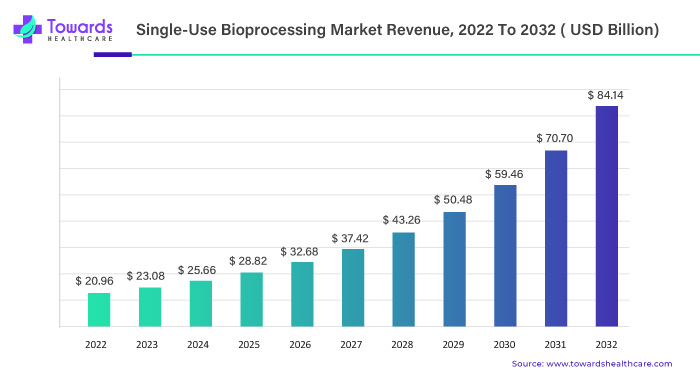

Growth and Trends in the Single-Use Bioprocessing Market (2023-2032)

The global single-use bioprocessing market is expected to experience significant growth, with revenue projected to rise from USD 20.96 billion in 2022 to an estimated USD 84.14 billion by 2032, reflecting a compound annual growth rate (CAGR) of 15.46% between 2023 and 2032. This surge is driven by an increasing demand for personalized medicines, a boost in research and development investments, and the growing adoption of decentralized clinical trials.

Download statistics of this report @ https://www.towardshealthcare.com/download-statistics/5030

The Impact of Single-Use Bioprocessing in the Evolving Biopharmaceutical Landscape

Single-use systems are making a significant impact on the bioprocessing industry by offering several advantages over traditional stainless-steel equipment. These systems are not only more energy-efficient but also easier to handle. Unlike stainless-steel systems, which require energy-intensive cleaning and sterilization after each batch, single-use systems are designed for one-time use, eliminating the need for these processes. This reduces energy consumption and minimizes waste. Additionally, the lightweight nature of the materials used in single-use systems contributes to lower energy costs during transportation and handling.

Another key factor in bioprocessing energy consumption is the need to control the temperature of the media, including both heating and cooling. Single-use systems can be more efficient in this regard, as they are designed with a higher surface area-to-volume ratio, improving heat transfer and further reducing energy use.

Lessons from Bioprocessing for Cell and Gene Therapy Manufacturing

As of February 2023, the U.S. FDA had approved over 20 gene therapies, with more than 1,000 gene therapy molecules in clinical trials. Cell and gene therapies, which use living cells or genetic material to treat or cure diseases, require highly specialized manufacturing processes. Single-use bioprocessing technology has become a game-changer in the production of these therapies, offering numerous benefits over traditional equipment.

The bioprocessing industry’s experience with single-use technology has taught valuable lessons that can now be applied to cell and gene therapy manufacturing. The key benefits include:

- Reduced contamination risk: Single-use systems eliminate the need for cleaning and sterilization between batches, reducing the risk of contamination, which is critical in therapies where cells or genetic materials are extremely sensitive.

- Increased flexibility: Since cell and gene therapies are often developed for small patient populations, manufacturers must be able to quickly adapt to changing needs. Single-use systems allow for easy adjustments to manufacturing processes without the need for extensive reconfiguration of equipment.

- Shorter turnaround times: Single-use systems are pre-sterilized and pre-assembled, which reduces the time spent on cleaning and preparation between batches, accelerating production timelines for time-sensitive therapies.

Additionally, single-use systems can significantly reduce capital expenses. Traditional stainless-steel equipment is costly to install and maintain, while single-use systems require less physical space and are often more cost-effective, especially for smaller manufacturers.

Single-Use Technology’s Role in Biologics and Beyond

Biologics, complex molecules produced using living cells, are increasingly in demand due to factors like an aging population, rising chronic diseases, and advancements in biopharmaceutical manufacturing. Single-use bioprocessing technology has become essential in meeting this demand, offering flexibility, reducing contamination risk, and speeding up production times.

Single-use technology is ideal for biologics production because it allows manufacturers to easily switch between different products or production processes. This flexibility is crucial, as biologics production runs are often short and must be adaptable to market needs. Furthermore, the reduced contamination risk and shorter turnaround times make single-use systems particularly valuable for biologics, where the quality and safety of the final product are paramount.

In addition to biologics, single-use technology is being increasingly used in the production of vaccines, cell and gene therapies, and biosimilars. The advantages it offers—such as reduced contamination risk and increased flexibility—make it an attractive option for producing these complex products.

Meeting the Rising Demand for Antibody-Drug Conjugates (ADCs)

The demand for antibody-drug conjugates (ADCs), which combine the potent targeting capabilities of monoclonal antibodies with the power of small molecules, is rapidly increasing in the biopharmaceutical industry. ADCs are being developed to treat a variety of cancers, and this surge in demand has highlighted the need for specialized manufacturing processes that ensure safety and efficiency.

Single-use technology is recommended for ADC production, as it offers the required containment and control measures while minimizing costs. Flexible single-use isolators, for example, can meet the high-containment standards necessary for handling ADCs, reducing the risk of exposure to toxic substances. These isolators have been shown to provide the level of protection required for safe production, especially when dealing with potent, hazardous materials.

One of the key benefits of single-use systems in ADC manufacturing is that they eliminate the need for cleaning and sterilization between batches, which helps speed up production and improve capacity. This is crucial for keeping up with the high demand for ADCs, which are used to treat cancer and other serious conditions.

Discover our detailed Table of Contents (TOC) for the Industry, providing a thorough examination of market segments, material, emerging technologies and key trends. Our TOC offers a structured analysis of market dynamics, emerging innovations, and regional dynamics to guide your strategic decisions in this rapidly evolving healthcare field – https://www.towardshealthcare.com/table-of-content/single-use-bioprocessing-revolution-how-innovative-therapies-are-transforming-healthcare

To own our research study instantly, Click here @ https://www.towardshealthcare.com/price/5030

You can place an order or ask any questions, please feel free to contact us at sales@towardshealthcare.com

About Us

Towards Healthcare is a leading global provider of technological solutions, clinical research services, and advanced analytics to the healthcare sector, committed to forming creative connections that result in actionable insights and creative innovations. We are a global strategy consulting firm that assists business leaders in gaining a competitive edge and accelerating growth. We are a provider of technological solutions, clinical research services, and advanced analytics to the healthcare sector, committed to forming creative connections that result in actionable insights and creative innovations.

Visit Dental Specifics: https://www.towardsdental.com

Explore the comprehensive statistics and insights on healthcare industry data and its associated segmentation: Get a Subscription

For Latest Update Follow Us: https://www.linkedin.com/company/towards-healthcare